projects.

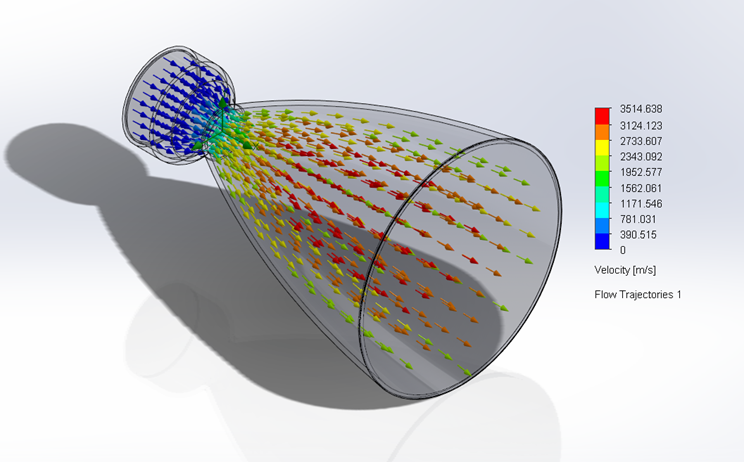

Rocket Engine Design

Given the requirements of a Liquid Methane-Liquid Oxygen (Methalox) rocket engine and aiming to maximize both specific impulse and burn time, I worked with a group of fellow Aerospace Engineering students to design a rocket engine capable of being used in a first-stage for low-earth orbit payload insertions.

Our design resulted in a dual-turbine, single preburner configuration, and my personal focus was on this specific preburner-turbine setup. After we used a chemical equilibrium solver to determine the near-impossibility of achieving 500 seconds of ISP at sea level and 500 seconds of burn-time — our initial challenge — we aimed to reduce the amount of moving parts by moving to a combination of a dual-turbine configuration and a single preburner. This is in contrast to leading designs in the Industry in the BE-4 from Blue Origin and the SpaceX Raptor, which use a single turbine configuration and a dual-turbine-dual-preburner configuration, respectively.

An interesting part of this project that requires much further research (and hopefully a Master’s or Doctorate degree) are the materials required to withstand the incredible heat generated from combustion of Liquid Methane and Liquid Oxygen, which are almost exclusively Ultra-High-Temperature-Ceramics (UHTCs). The fabrication of these UHTCs for use in high efficiency rocket engines is something I would like to explore in the future.